WP Leader: CNAM

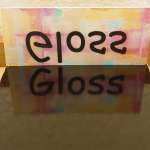

WP2: Gloss

Gloss is a visual attribute that is recognised as the second most relevant  beside colour, involved in the criterions of choice of an object. If the measurement of colour is today rather well developed, it appears that gloss measurement field is poor. The most popular device that quantifies gloss is the glossmeter, which makes measurements according to the ISO2813 standard. This instrument correlates with the sensation of gloss and is useful in monitoring the day-to-day quality of a product. However, for specular gloss, the gloss standard is inadequate for many current applications for example when describing metallic coatings or nacre finishes, or comparing two different materials. The main criticism comes from the fact that the measurement is based on the determination of the flux reflected in the specular direction inside a large and fixed rectangular aperture, whereas the human visual system performs a sophisticated and dynamic analysis.

beside colour, involved in the criterions of choice of an object. If the measurement of colour is today rather well developed, it appears that gloss measurement field is poor. The most popular device that quantifies gloss is the glossmeter, which makes measurements according to the ISO2813 standard. This instrument correlates with the sensation of gloss and is useful in monitoring the day-to-day quality of a product. However, for specular gloss, the gloss standard is inadequate for many current applications for example when describing metallic coatings or nacre finishes, or comparing two different materials. The main criticism comes from the fact that the measurement is based on the determination of the flux reflected in the specular direction inside a large and fixed rectangular aperture, whereas the human visual system performs a sophisticated and dynamic analysis.

The aim of this work package is to improve in the comprehension of the glossiness of surfaces, in order to propose new measurement procedures that will correlate with the visual sensation, and take into account the complexity of the gloss perception.

Task 2.1: Manufacturing of the gloss artefacts

Start: September 2013, End: February 2014

The aim of this task is the production of artefacts dedicated to the study of gloss.

Background: We know that gloss originates from the reflection of the light on the surface of the material in the specular direction. More accurately, the sensation of gloss depends of the shape of the specular peak. If the peak is sharp, the sample looks glossy, if the peak is smooth, the sample looks matte. The height of the specular peak according to the background is also important. That means that for a given specular peak, a white surface will appear less glossy than a black one.

Description of work: The research department of St-Gobain Glass, well known company of glass manufacture has accepted to provide their knowledge and their dedicated facilities for this task. Their skills in the mastering glass surfaces will be a great benefice for this task. Within this task, artefacts will be produced that will generate different shapes of specular peak when they are illuminated. The shape of the specular peak depends upon the roughness and the refractive index of the material.

Task 2.2: Measurements of the BRDF of the samples

Start: May 2014, End: August 2014 + Start: March 2016, End: June 2016

The aim of this task is to determine the BRDF outside of the specular reflection direction for the entire set of gloss artefacts (48 samples) issued from task 2.1, by performing measurements in a predefined set of illumination and viewing geometries.

Description of work: The human eye perceives luminance and gloss as an achromatic phenomenon. Thus the appropriate measurement is the measurement of a “photometric” BRDF (luminance on illuminance) that will reflect the evaluation of how the perceived light is spread in the space around the sample. With 48 samples, 6 angles of illumination and about 20 angles of observation, this task will generate a significant amount of data which will lead to a full understanding of gloss. The task will be led by CNAM and the workload will be shared with REG (KU Leuven) and CMI. It will be performed in two different phases. A first campaign of measurements will be performed at the beginning of the project (May 2014 – August 2014); and a second campaign will be performed at the end (March 2016 – June 2016) This will act as a control to confirm that the manipulation of the artefacts during the visual experiments will not have modified (aged) the BRDF of the samples during the timescale of the JRP.

Task 2.3: Improvement of the traceability of reference facilities for specular peaks measurements on gloss artefacts

Start: February 2014, End: May 2015

The aim of this task is to carry on BRDF measurements inside and around the specular peak for glossy artefacts, on different type of gonioreflectometers available in the JRP consortium that present different technologies.

Background: Theoretically, the BRDF, being defined as a ratio of infinitesimals, is a derivative with “instantaneous” values that can never be measured directly. Real measurements involve non-zero intervals of the parameters, and hence can yield only average values over those parameter intervals. In practice, the use of an extended illumination spot causes the effect of light bundle and detector aperture convolution on the measured BRDF. Both convolutions result in an angular broadening and a reduced peak height of the real BRDF. In absence of any standardisation regarding the optical design of BRDF measurement instrumentation, the direct comparison of measurement results obtained on different devices is problematic. Indeed, different optical designs (e.g. dimensions of illumination and receptor apertures) engender different results. If this problem has negligible effects on the measurements performed on samples that present a relatively smooth BRDF, it becomes crucial on samples that presents peaks shape BRDF. For high gloss samples, the weight at middle height can drop to less than 0.3°.

Description of work: The same set of samples will be measured on gonioreflectometers available in the JRP consortium that present different technologies. This comparison will provide a state of the art in term of BRDF angular discrimination that will be of a great interest for the measurement of gloss. The obtained datasets from all BRDF measurement facilities will be compared, in order to quantify the convolution effect. The data sets will be analysed and possible solutions to deal with this convolution issue will be investigated and formulated.

Task 2.4: Measurement of the BRDF in the specular peak area

Start: December 2013, End: May 2014 + Start: May 2016, End: June 2016

The aim of this part is the measurement of the shape of the specular peak with an angular resolution close to the resolution of the visual system.

Background: Depending on the materials surface roughness, the specular peak could have either a Gaussian envelope or a Lorentzian envelope. The human visual system is able to make a difference between the different types of material. Furthermore, it is assumed, but not proven, that it uses the shape of the specular peak to interpret small variations of gloss and hence to recover the nature of the material. Therefore, this will be investigated in detail within this task.

Description of work: A measurement of the specular peaks with a high resolution of 0.2 μsr will be performed with dedicated instrumentation at CNAM to explore the 3D shape of the specular. A study on the evolution of the shape of the specular peak according to the roughness and the geometrical conditions of illumination will be done. The data will be made available to WP4 and WP5. As for task 2.2, the measurements will be performed in two different phases. A first campaign will be done at the beginning of the project (December 2013 – May 2014). A second campaign will be performed at the end (May 2016 – June 2016). This will act as a control to confirm that the manipulation of the artefacts during the visual experiments will not have modified (aged) the BRDF of the samples during the timescale of the JRP.

Task 2.5: Measurement of the roughness and of the topography of the samples

Start: January 2014, End: August 2014

The aim of this task is to use both optical and mechanical methods to determine the roughness of the artefacts under investigation.

Background: Roughness and glossiness are strongly correlated and it is therefore of great interest to relate the visual gloss of the material with the structure of its surface. As both micro- and macroscopic surface features are known to influence the perceived gloss, haze and DOI (distinctness of image), we propose to use different measurement techniques to capture important surface properties.

Description of work: In this task, the surface roughness and structure of a selection of at least 6 samples will be measured.

Task 2.6: Measurement of the specular gloss, haze and DOI of the samples

Start: September 2014, End: November 2014 + Start: March 2016, End: May 2016

The aim of this task is to carry out measurements of the specular gloss and of the haze of the artefacts in order to be able to communicate in a clear manner with the industrial and researcher community.

Background: Currently, gloss and haze are measured using different measurements standards and equipment. The two most commonly used measurements are the measurement of the specular gloss according to the ISO2813 standard and the measurement of the haze according to the ASTM E430-97.

Description of work: The specular gloss and haze will be measured according to these standards. As in task 2.2 and 2.4, the measurements will be performed in two different phases (i.e. a first campaign at the beginning of the project (September 2014 – November 2014), a second campaign at the end, (March 2016 – May 2016) in order to ensure that the manipulation of the artefacts during the visual experiments will not modify the gloss and haze of the samples.

Task 2.7: Make a proposal for a gloss measurement and scale

Start: May 2016, End: July 2016

The aim of this task is to propose an alternative to the ISO2813 standard for gloss measurement.

Description of work: From task 5.6, the relevant parameters and their weights with the different perception functions to recover the sensation are obtained. In this last task the results from the other tasks will be summarised and analysed. An alternative to the ISO2813 measurement standard will be proposed with the objective to be more in-line with the manufacturer of gloss materials stakeholder community. A minimum of relevant parameters and measurement geometries requested to be able to recover the sensation of gloss will be defined. As part of the Impact work package for this JRP, this work will be submitted to a technical committee of the CIE, Division 2, devoted to gloss measurement. Combined with other works on the subject, it will provide a contribution to a new standard for a gloss measurement that will be useful for industries that are specifically interested in the appearance of gloss.